In-line inspection

Magnetic inspection

Magnetic method of in-line inspection is based on registering stray magnetic fields, arising from magnetization of the wall of the pipeline. The essence of this method is that if there is any anomaly in the wall of the pipeline, a part of magnetic flow is dispersed on the anomaly, and this may be recorded by the sensor, located close to the pipeline surface.

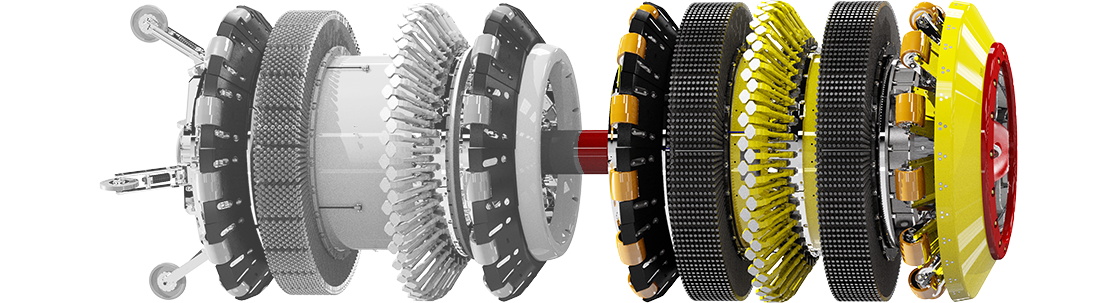

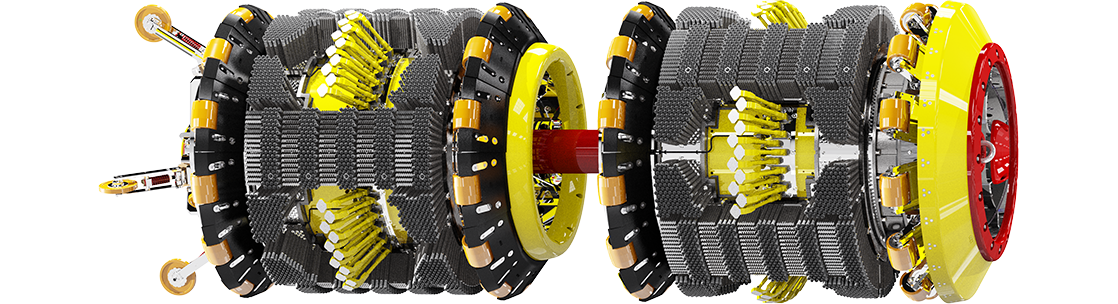

Magnetizing the wall of the pipeline by ILI tools is provided through permanent magnets, placed on a cylindrical yoke, and through flexible metallic brushes, transferring magnetic flow from the magnets to the wall of the pipeline.

- high sensitivity to metal loss features

- high resolution capacity

- high stability of monitoring results

- visibility of monitoring results

- minimum faulty actuation

- high security and producibility of construction of ILI tools

- Magnetic Flux Leakage (MFL)

- Transverse Field Inspection (TFI)

- Introscope (MFL+)

MFL tools

Magnetic flux leakage tools are designed to detect and record:

- corrosion anomalies (corrosion, pitting, pinhole, circumferential grooving)

- artificial defects of circumferential positioning

- circumferential metallurgical anomalies

- circumferential stress-corrosion cracks

- girth weld anomalies

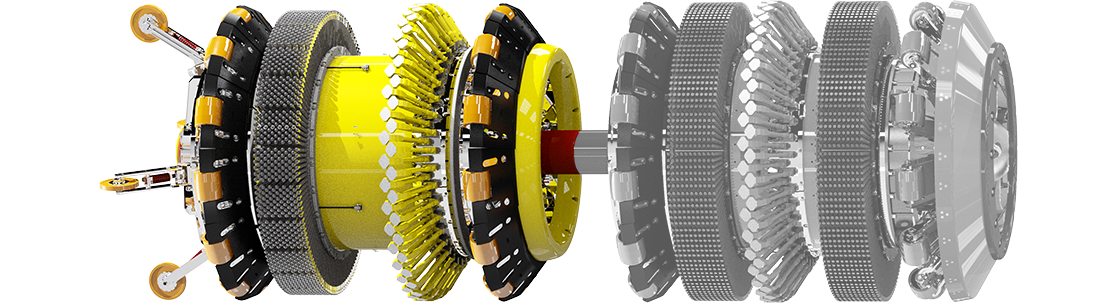

TFI tools

Transverse field inspection tools (TFI) are designed to detect and record:

- corrosion anomalies

- artificial defects of axial positioning

- axial metallurgical anomalies

- axial stress-corrosion cracks

- seam weld anomalies

MFL+ introscopes

Magnetic introscopes MFL+ are designed to detect and record:

- corrosion anomalies on the inner surface of the pipeline

- metallurgic anomalies on the inner surface

- girth weld, longidutidanl weld and spiral weld anomalies

- pipe geometry imperfection

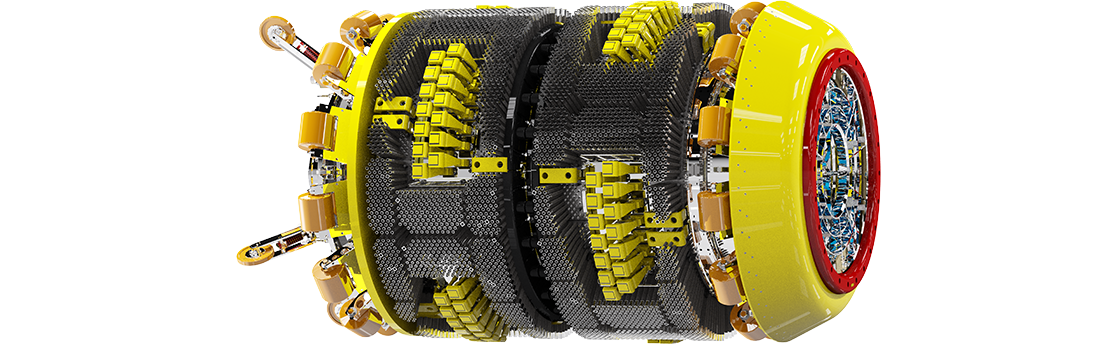

Combined magnetic-acoustic inspection

Combined magnetic-acoustic in-line inspection is based on electromagnetic-acoustic (EMA) method of excitation and registration of ultrasound shear vibrations in the metal of controlled pipeline, which enables to execute In-line inspection without utilization of a contact liquid.

Combined magnetic-acoustic tools

Combined magnetic-acoustic tools are designed to:

- identify zones of variously oriented cracks at an early stage of development both in base metal and girth welds

- register metal loss features and laminations, estimate its depth by an acoustic method, monitor the growth of corrosion anomalies

- define the type and estimate condition of external coating