Electronic Geometry Survey

Data recorded by electronic geometry pigs make it possible to reveal anomalies of internal pipeline bore and estimate their sizes. During electronic geometry survey, girth welds and pipeline construction features are registered, as well as pipeline passability is estimated for further inspection by magnetic or ultrasonic intelligent tools.

Analysis of signals of navigation unit, if the electronic geometry pig is equipped, makes it possible to detect and classify bends (deviations of the pipeline axis from the straight direction) and calculate geodetic coordinates of all the detected anomalies and pipeline construction features.

Electronic Geometry Pigs (EGP)

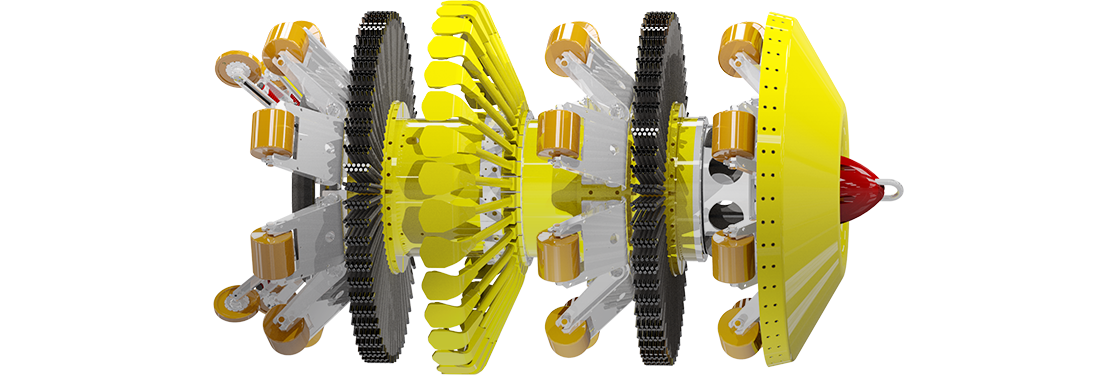

EGP is intended for measurement of internal pipeline bore profile and determination of pipeline axis position.

Operation principle of electronic geometry pig is based on reconstruction of pipe internal cross section according to the data of lever measuring system. Cross section is reconstructed by means of recording angular position of the levers covering 100% of pipe internal circumference. Pipeline axis position is determined with the use of inertial navigation system data.

Pipeline features and deformations of pipeline surface detectable by electronic geometry pig:

- Pipeline location features

• bends (turns)

• bend radius

• turn angle

- Cross section deformation

• ovalities

• dents

• wrinkles

- Construction features